What are the five biggest Fridge Temperature Management Risks?

In food, healthcare, and vaccine storage environments, refrigeration looks simple on the surface: plug it in, set the temperature, and shut the door. In reality, fridge and freezer temperature management is one of the most common points of failure in the cold chain. A single temperature excursion can mean thousands of dollars in wasted product, compliance issues, and reputational damage.

Good temperature control is more than just checking a display occasionally. It involves understanding the risks that can quietly undermine your efforts to keep stock safe, with regards to food and also medications and vaccines. Here are the five biggest risks in fridge temperature management—and how a wireless monitoring system like Temp Assure can help you stay ahead of them.

1. Relying on manual fridge temperature checks is a management risk

Many organisations still rely on staff to record fridge temperatures once or twice a day. While that may satisfy a basic checklist, it leaves huge gaps in your records. If a fridge fails at 2am and someone checks it at 9am, there are seven hours of unknown temperature history. Product may have been out of range for much of the night, but the paper log will show only the reading at 9am.

Manual checks are also prone to human error. Staff are busy, records may be rushed or copied from the previous day, and the person taking the reading might not fully understand the compliance requirements. A wireless monitoring system continuously logs temperature, so you have a complete history—not a few snapshots on a clipboard.

2. Undetected equipment failure

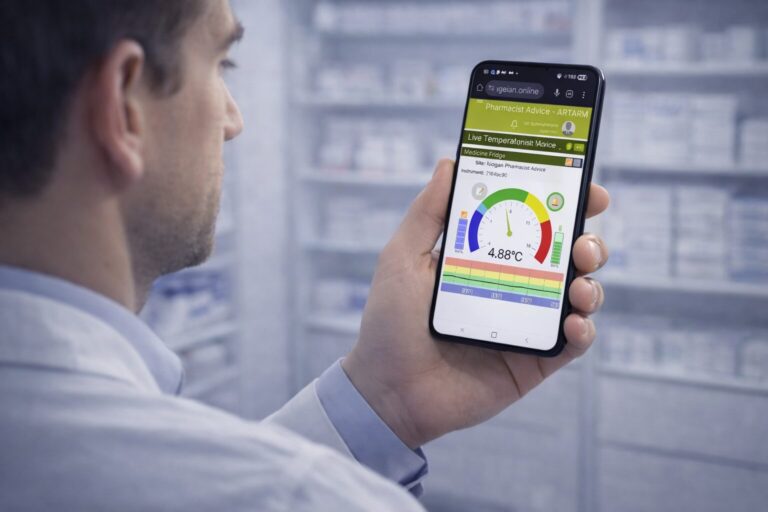

Fridges and freezers do not usually fail when it is convenient. Compressors can fail overnight, doors can be left ajar, or thermostat sensors can drift out of calibration. Without real-time alerts, these problems are often discovered only when someone notices warm stock or a strange smell.

A system such as Temp Assure uses transmitters like the CTX900A and CTH900B to monitor temperature continuously and send alerts when readings move out of range. Alerts can be sent by SMS, email, and via gateway alarms, so issues are addressed quickly rather than hours later.

3. Poor sensor placement is a fridge temperature management risk

Even when monitoring is in place, the location of the sensor inside the fridge makes a big difference. Placing the temperature probe too close to the cooling plate, near the door, or in a dead corner can result in readings that do not accurately represent the product temperature.

Sensors should typically be positioned where they best reflect the temperature of the stored goods, not the coldest or warmest point in the cabinet. In some cases, using a thermal buffer (such as a small bottle or block) helps smooth short-term fluctuations when doors open, mimicking product temperature more closely. A well-designed system supports these techniques so your readings align with what really matters: product safety.

4. Incomplete or inaccessible records

For compliance and audit purposes, you need more than a good fridge—you need evidence. Regulators and auditors may ask to see historical temperature records, not just a verbal assurance that everything was fine. Paper-based systems are easily lost, damaged, or incomplete, especially over long periods.

With cloud-based wireless monitoring, temperature logs are stored automatically and can be accessed anytime. Reports can be generated for specific dates, units, or sites and exported for audits. Instead of chasing missing clipboards or deciphering handwriting, you can present clear, digital records that demonstrate consistent compliance.

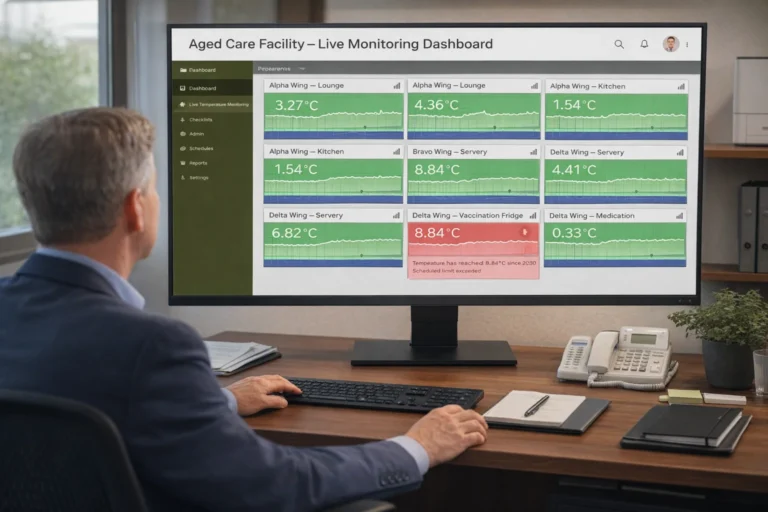

5. No visibility across multiple sites

Many organisations manage temperature-sensitive stock at more than one location—aged-care groups, pharmacy chains, hospital networks, or multi-site food operators. If each site operates independently with manual logs, there is little central oversight. Problems may go unnoticed until they become significant failures.

A system like Temp Assure allows you to monitor multiple sites from a single portal. You can see which fridges are in range, which ones have generated alerts, and where patterns are emerging. This makes it easier to standardise procedures, identify problem equipment, and ensure that every site meets your safety and quality standards.

Bringing it all together

Fridge temperature management fails most often not because people do not care, but because the tools are incomplete. Manual checks, single-point sensors, and paper-based logs can only take you so far. The biggest risks—missed excursions, undetected failures, poor placement, weak records, and fragmented oversight—are all addressed by continuous, automated monitoring.

By implementing a wireless system with certified-accuracy sensors, reliable gateways, and a secure online portal, you can move from reactive problem-solving to proactive control. That is what Temp Assure is designed to provide: confidence in every degree, every day.