Why bother with food safety automation?

Food safety is non-negotiable in any organisation that handles food—whether it is an aged-care facility, hospital, childcare centre, commercial kitchen, or quick service restaurant. The challenge is that safety tasks are often layered on top of already busy roles. Staff are expected to prepare food, serve residents or customers, clean, and also maintain detailed safety records.

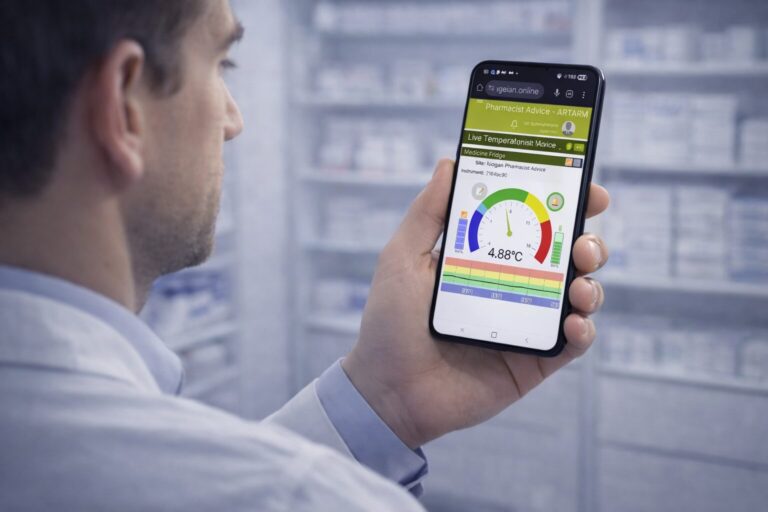

Food safety automation offers a way to meet regulatory requirements without overloading staff. Instead of relying on clipboards and manual logs, wireless monitoring systems and smart devices can take on much of the recording and checking work. Here is how automation meaningfully reduces labour in food safety while improving reliability at the same time.

Replacing repetitive manual temperature checks

Traditional food safety routines often require staff to record fridge and freezer temperatures at regular intervals—sometimes several times per day. Each check involves locating the thermometer, opening the unit, reading the display, writing down the value, and signing off. Over the course of a week, this adds up to a significant amount of time.

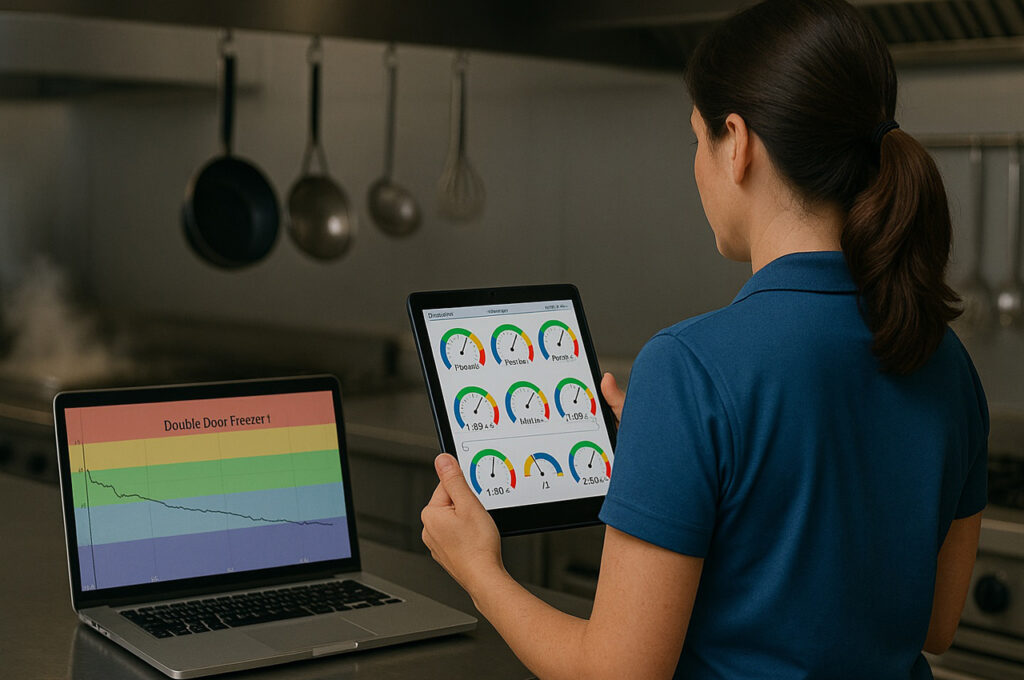

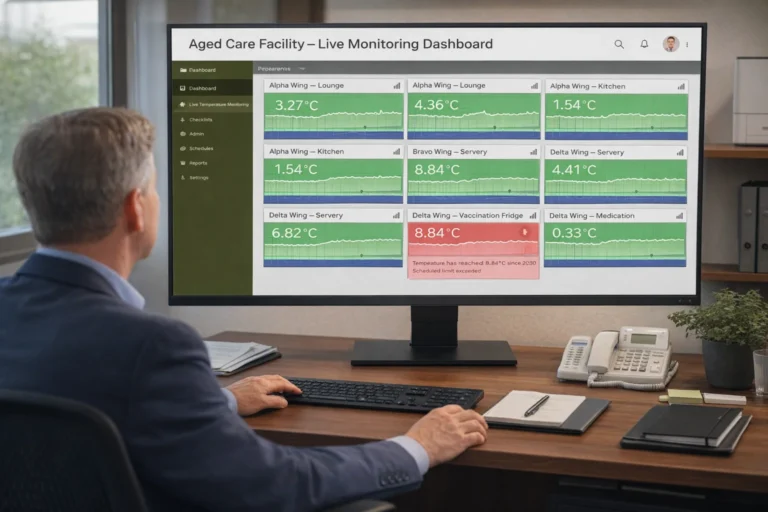

Automated wireless monitoring replaces these manual checks with continuous logging. Transmitters such as the CTX900A and CTH900B sit in fridges and freezers, capturing temperatures around the clock and sending data to a central gateway. Staff no longer need to interrupt their workflow to perform repetitive readings; the system does it for them.

How Food safety Automation reduces paperwork and data entry

Paper forms and spreadsheets consume time and create risk. Forms have to be printed, completed, stored, and later retrieved for audits. Each manual entry is an opportunity for errors, omissions, or inconsistencies. If records are not completed properly, the organisation can appear non-compliant, even if the food has been kept safely.

Automated monitoring systems record temperature readings directly into a secure database. Reports can be generated with a few clicks, filtered by date, unit, or site. This greatly reduces admin time and removes the need for staff to manually transcribe data.

Food Safety Automation means fewer Staff Interruptions

When safety tasks are manual and repetitive, they can pull skilled staff away from more important duties—such as caring for residents, serving customers, or managing the kitchen. Automation does not replace the need for trained personnel, but it frees them from low-value tasks so they can focus on supervision, decision-making, and quality.

For example, rather than spending time walking around to check fridges, staff can respond only when an alert indicates that something needs attention. This shift—from routine checking to exception-based response—is one of the clearest ways automation reduces labour.

Food Safety Automation means fewer call-outs and emergency responses

A well-configured monitoring system sends alerts before a minor problem becomes a major one. If a fridge door is left ajar or a unit begins to drift out of range, an alert can be triggered early. Staff can address the issue during normal working hours instead of discovering spoiled stock later and scrambling to replace it.

This proactive approach reduces the need for emergency call-outs, last-minute stock runs, and unplanned overtime. It also supports better planning; if a unit is repeatedly problematic, it can be repaired or replaced before it fails completely.

Guided processes for probe checks

Not all food safety tasks can be fully automated. Cooking and cooling checks still require someone to measure product temperature. However, smart tools can make these processes faster and more reliable. A certified food probe such as the CFP200A, with an on-device display and checklists, can guide staff through the necessary steps and record the readings electronically.

Instead of filling out paper forms after each batch, staff follow prompts on the device, confirming that each required check has been completed. This reduces the chance of missed steps and eliminates the need to enter data later.

Food Safety Automation Means Improved compliance with less effort

One of the main concerns with reducing manual tasks is the fear that standards will slip. In practice, automation tends to improve compliance. The system never forgets to log a reading, never copies yesterday’s numbers, and never misreads a thermometer. Staff can still review and sign off on records, but they are working from a complete, accurate data set.

Audits also become easier. Rather than gathering paper files from multiple locations, managers can log into a portal. They generate reports, and demonstrate compliance with a clear digital trail. This can save many hours of preparation whenever inspections are due.

The bigger picture: cost and culture

Labour savings from automation do not just show up as minutes saved on individual tasks. Over time, they reduce stress on staff, allow better allocation of resources. They support a culture of safety where people focus on understanding risks rather than filling out forms.

When continuous monitoring, automated alerts, and guided checklists work together, the organisation gains stronger control over its food safety obligations with less daily effort from frontline staff.

That is the value of a system like Temp Assure: it does the background work so your team can concentrate on care, service, and quality.