Why do certified temperature probes matter?

Measurement with certified temperature probes is at the heart of food safety and vaccine storage. Cooking, cooling, reheating, and holding temperatures all depend on reliable thermometers and probes. Yet one crucial aspect is often overlooked: whether the probe itself is certified for accuracy.

Using a low-cost, uncertified probe may seem acceptable when you are simply “checking if something is hot enough”. But from a compliance and risk perspective, uncertified devices can leave dangerous gaps. Regulators and auditors increasingly expect not only records of temperatures but also evidence that the measuring instruments are accurate.

What does temperature probe certification mean?

Certification means that a probe has been tested against a known reference and its accuracy has been verified within a defined tolerance—such as ±0.2°C over a specified range. The results are usually documented in a certificate that can be referenced during audits.

In systems like Temp Assure, a certified food probe such as the CFP200A is designed and calibrated to meet tight accuracy requirements for food safety work. This gives you a defensible, documented basis for the measurements you rely on every day.

Accuracy of certtified temperature probes vs. trust

A thermometer that has never been checked may appear to work—it gives readings that seem reasonable, and food is served without obvious issues. However, small errors can have big consequences. A probe that reads 2°C low might show 73°C when the actual product temperature is 75°C or higher. In some cases, that means food that looks compliant on paper is, in reality, undercooked or inadequately reheated.

Certified temperature probes are not just about being more precise; they are about providing trust. When inspectors ask how you know your measurements are accurate, you can point to a specification and certification process rather than relying on assumptions.

Audit and legal defensibility

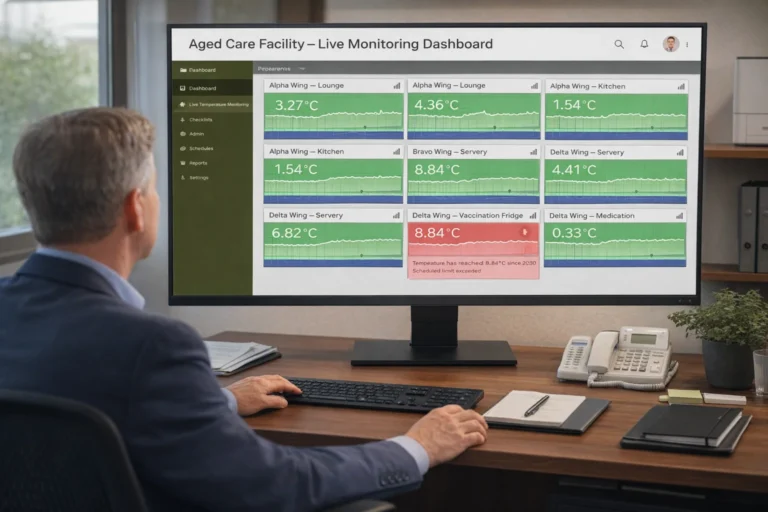

If something goes wrong—such as a suspected foodborne illness or vaccine temperature excursion—investigators will look for evidence. They will ask not only what temperatures were recorded, but how those temperatures were measured. Being able to demonstrate that you used certified probes that are appropriate for the task can make a significant difference.

A certified probe, coupled with clear procedures and records, shows that you took reasonable steps to ensure safety. An uncertified, consumer-grade thermometer makes that argument harder to sustain.

Managing drift and re-certification

All temperature sensors can drift over time. Certification is, therefore, not a one-time event but part of an ongoing quality process. A good system allows probes to be re-certified or recalibrated periodically, so you maintain confidence in the readings.

Temp Assure is designed with certification and re-certification in mind. Probes can be checked against reference standards and adjusted where appropriate. This helps you align your procedures with regulatory expectations and internal quality policies.

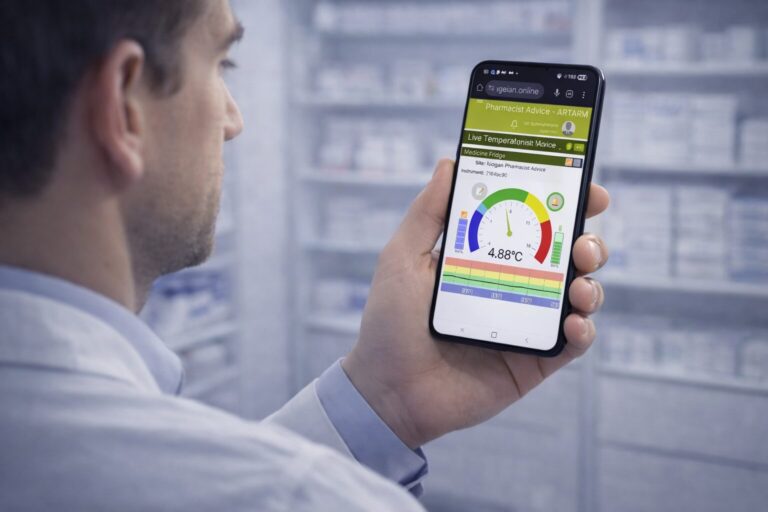

Integrating certified temperature probes into your workflow

For certified temperature probes to deliver maximum benefit, they need to be easy for staff to use. Devices like the CFP100A and CFP200A combine certified accuracy with practical features: an on-device display, robust construction, and the ability to support checklists and logging.

Staff can carry out cooking and cooling checks, see clear prompts, and have readings captured electronically where appropriate. This reduces the likelihood of transcription errors and missing data while ensuring that the measurements themselves are trustworthy.

A small investment with a big impact

In many operations, the cost difference between a basic probe and a certified one is modest compared to the value of the stock being protected—or the potential cost of a compliance failure. Investing in certified probes is a simple, tangible step towards stronger food safety and cold-chain control.

When combined with continuous monitoring of fridges and freezers, certified probes complete the picture: you know that both your storage and your spot checks are based on accurate, defensible measurements. That is why certified probes are not a luxury—they are a core part of a modern compliance strategy.